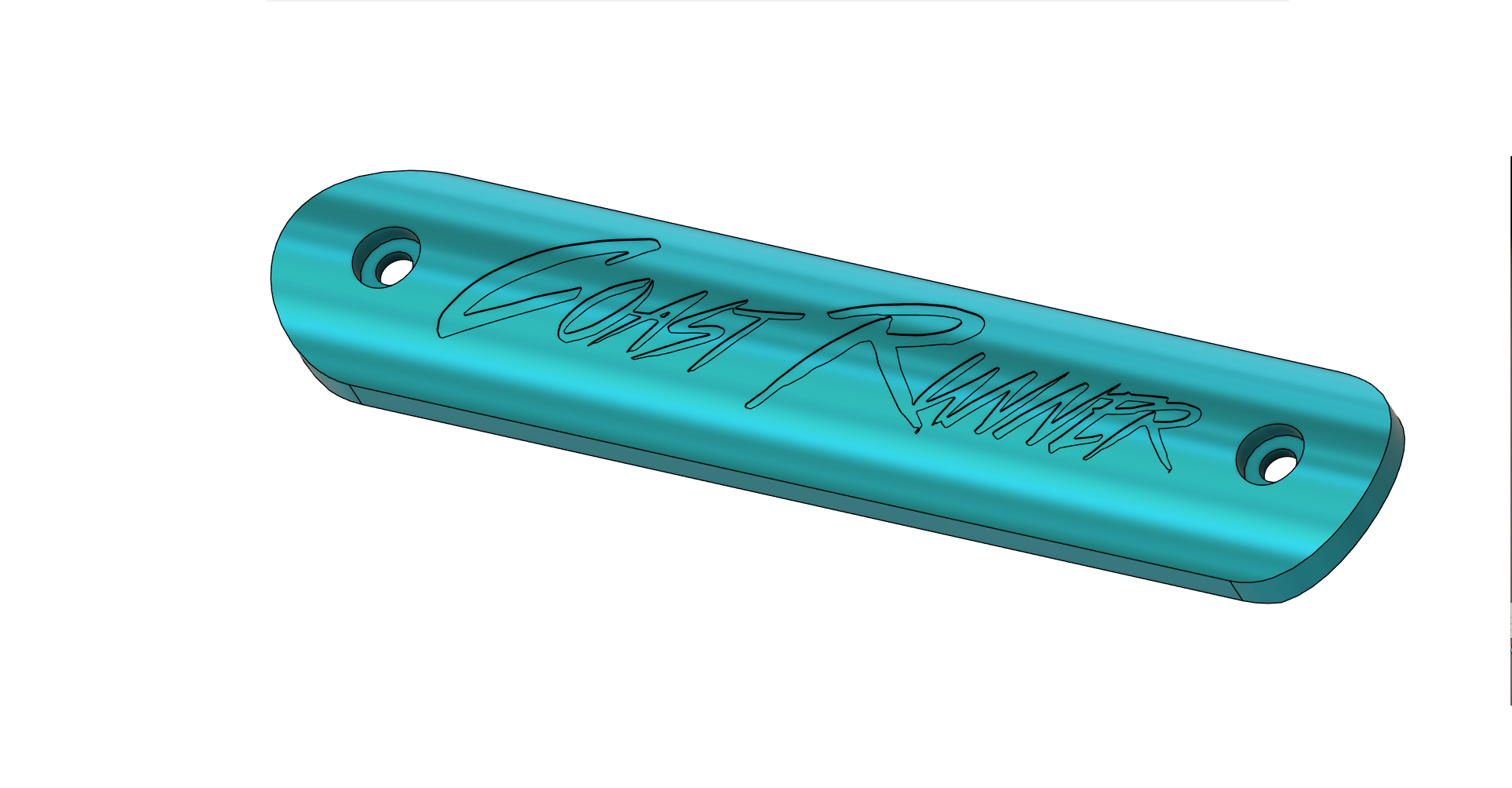

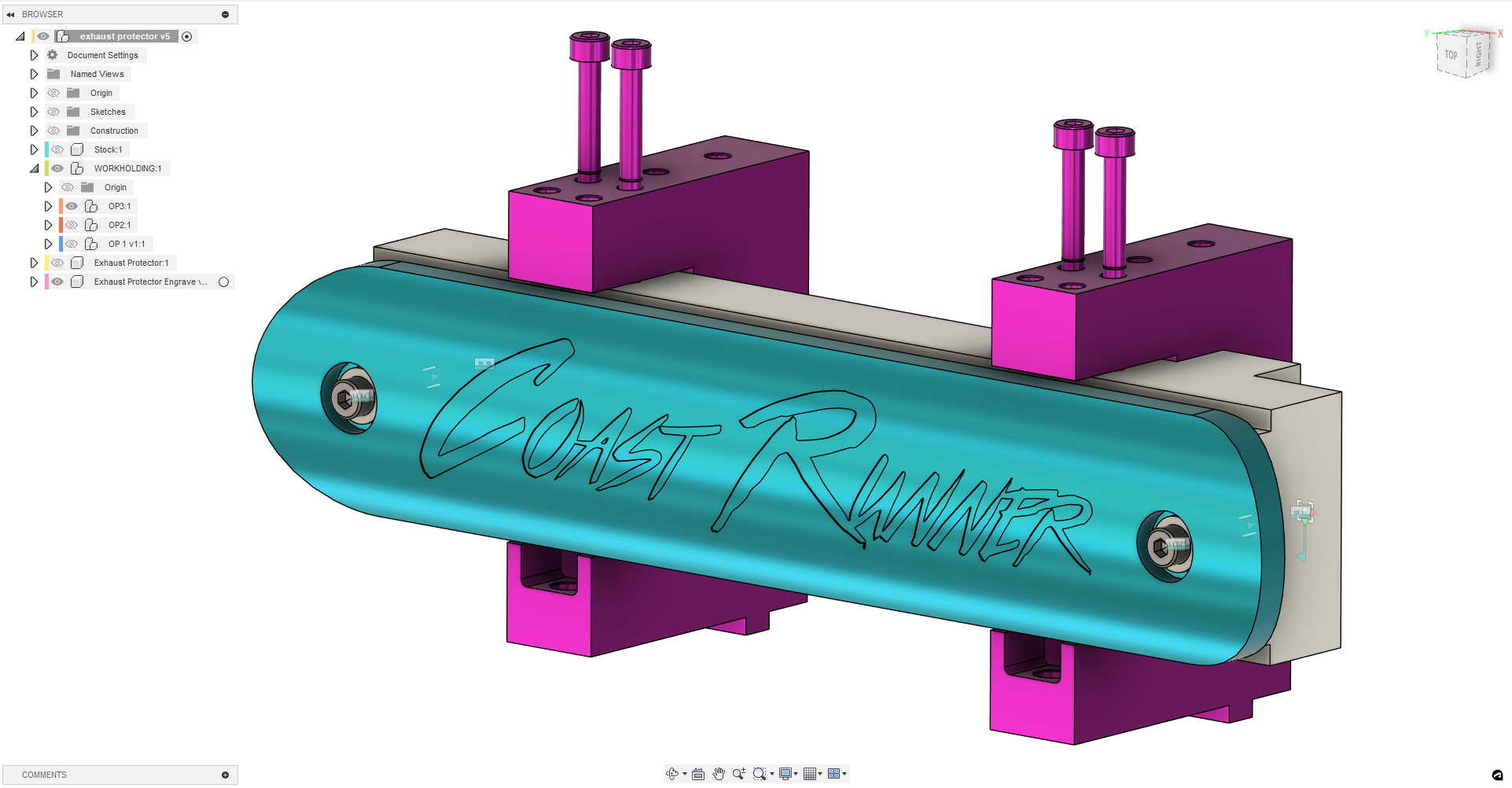

EXHAUST PROTECTOR

Description

TITLE:

EXHAUST PROTECTOR

CR-1 Millable Project

CREATOR:

Hearts and Minds

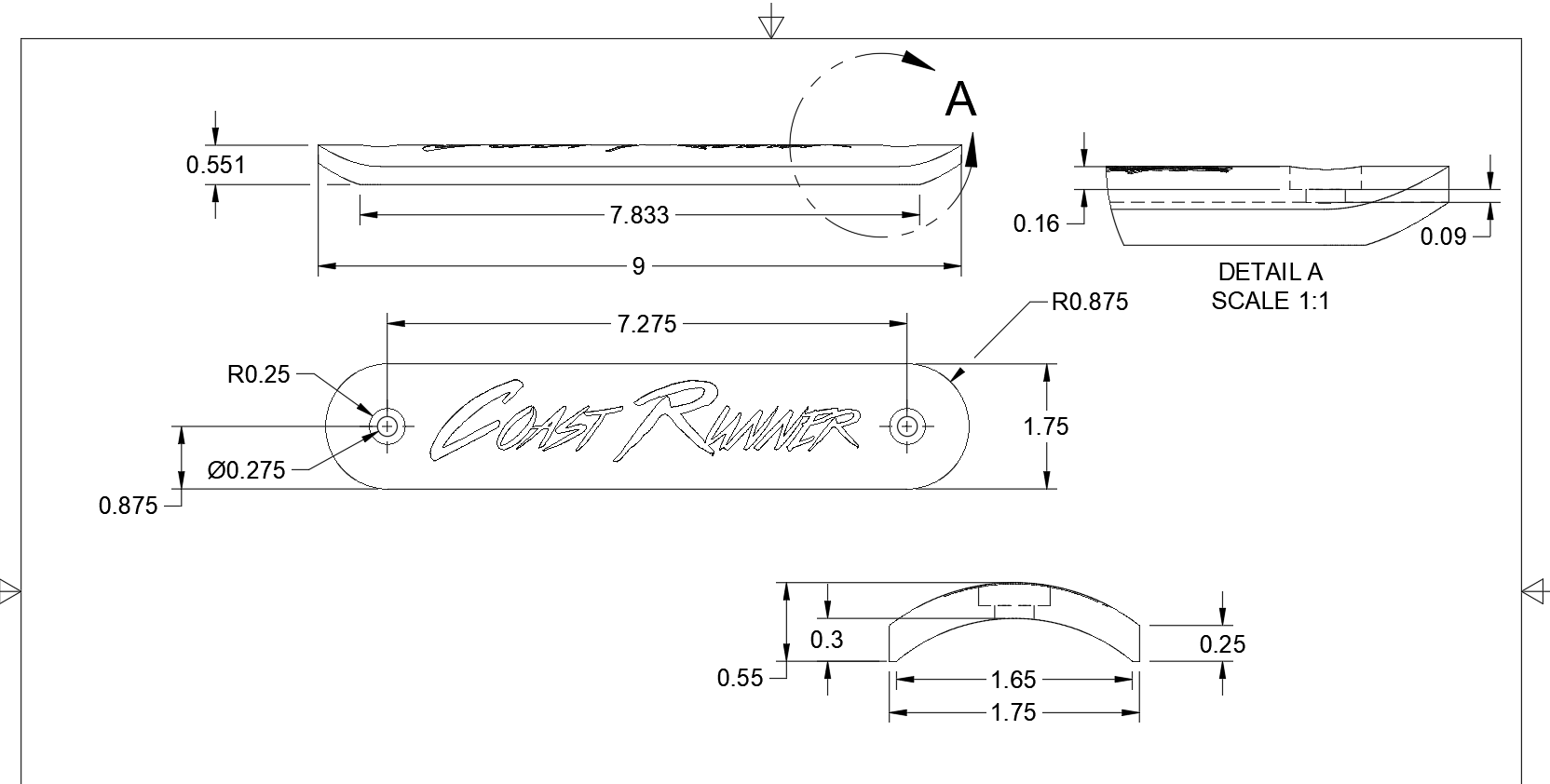

This is an exhaust protector from my friend's motorcycle. The design is as such to allow adjustments for the engraving for whatever you could possible want. The protector is meant to be connected to inserts that go on pipe clamps to directly mount to the exhaust pipe of any given motorcycle. This design requires a 3D printed insert included in the STEP files for OP3. Note that this design maxes out the Y travel of the machine in practice so be sure to center with stock as best you can with manual travel of the Y axis. This program does not include a CRPROJ due to simplicity.

STOCK:

Aluminum 6061

9.2" x 1.8" x 0.75"

1.75" x 0.75" stock from mcmaster carr is totally useable for the design since the wcs is centered. Try to get your cut between 9.1" and 9.25" for the length so that the endmill does not bog down.

TOOLS:

You will need to jog the machine using manual mode in order to replace the tools. Make sure the tool that is installed in the machine is the tool called for with the tool.

T1:

DIA: 1/4"(0.25") OAL: 1.125"

3 Flute, Square - 40° Helix, Variable Pitch, End Mill for Aluminum Alloys & Non-Ferrous Materials

Vendor: Helical

Product: 81994

T3

DIA: 1/8"(0.125") OAL: 0.62"

2 Flute, Ball - 45° Helix, End Mills for Aluminum Alloys & Non-Ferrous Materials

Vendor: Helical

Product: 17032

T4 (engraving only)

DIA:5/32"(.03125") OAL: 1.50"

4 Flute Ball Nose End Mill

Vendor: M.A. Ford

Product: 14003120

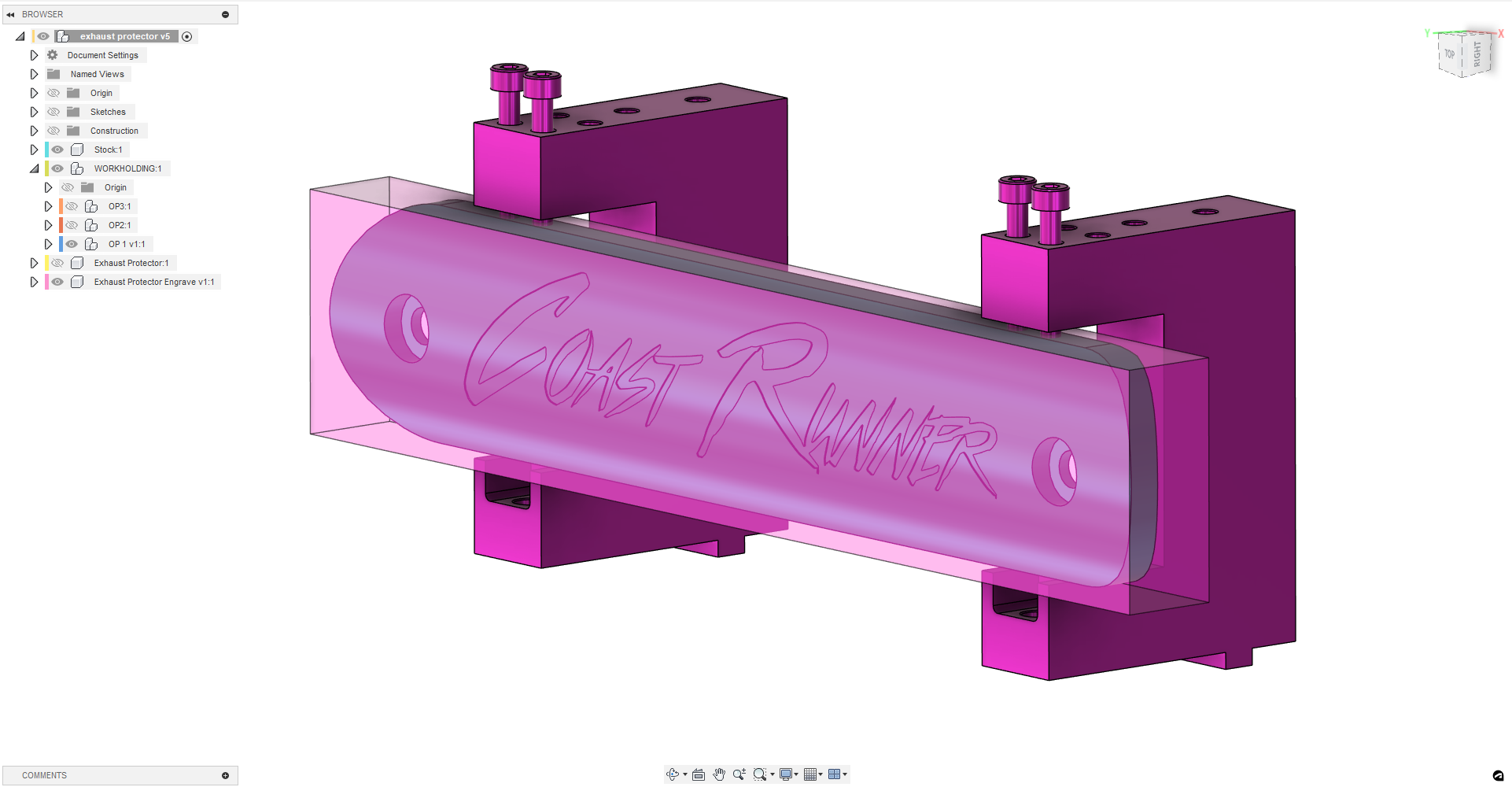

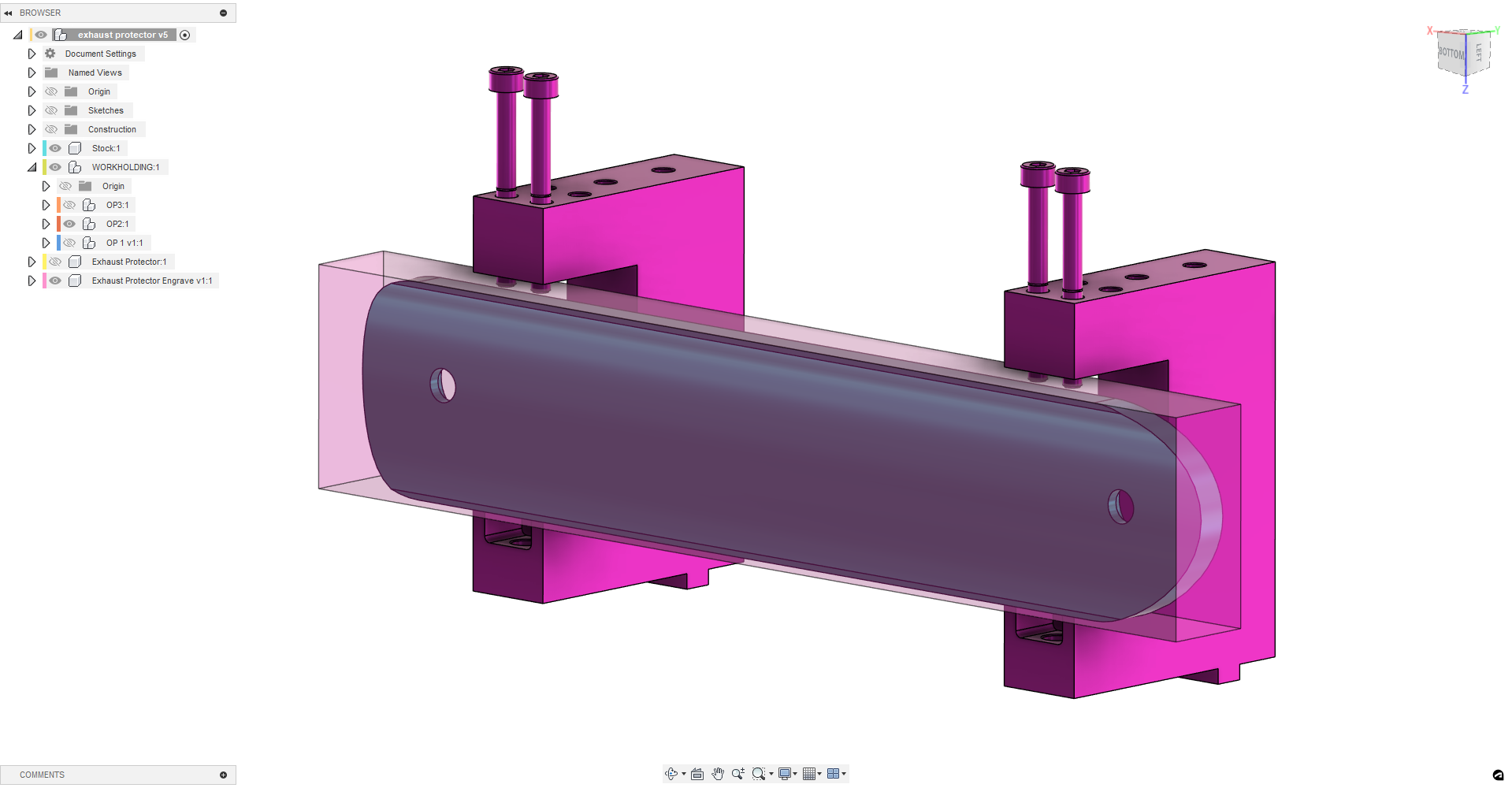

WORKHOLDING:

2x Universal Clamp + Accessories for mounting to T-Slot & 4x M5 bolts (https://www.coastcad.com/project/universal-clamp~rxuxte2su0bslrh)

2x M4x0.7 x 40 bolts

4x M4 washers

2x M4x0.7 Nuts

1x 3D printed insert (located in STEP)

WORK COORDINATE SYSTEM:

Set using the G55 WCS. Can be done manually or with conductive probing. X/Y for all 3 ops is center of part and Z is top of stock/part.

OPERATIONS:

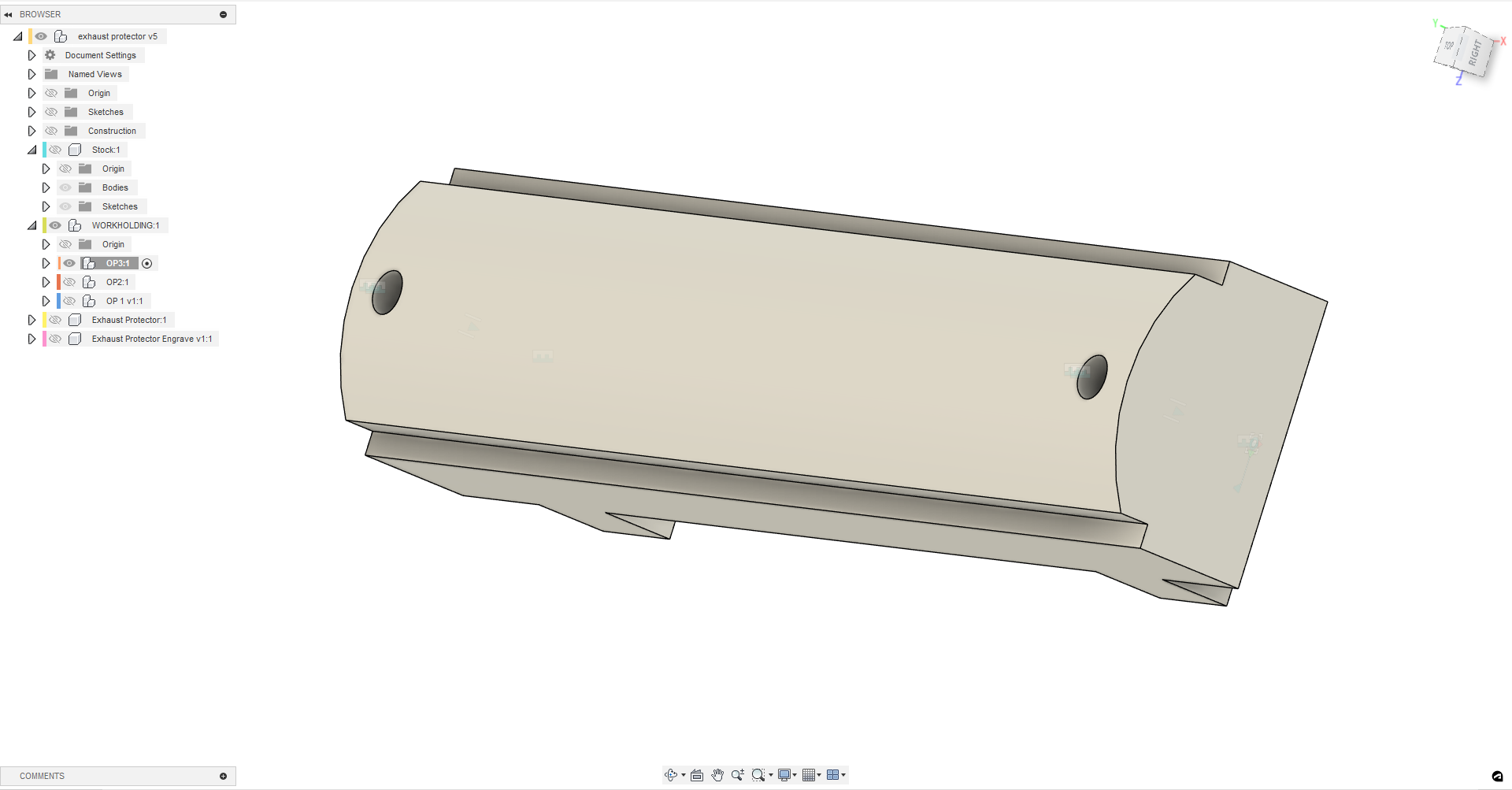

OP1:

Center stock in the machine. Use manual job to verify the stock is centered. The back of the stock is 0.5" from the back of the jaws but the only critical consideration is that the stock is 0.3" away frow front of jaws for facing. This operation faces and bores out the M4 mounting points for OP3. You can use a T-Slot stop so that X/Y is easy to set for OP2. Tighten the M5 bolts the same way you would with a car tire (alternating pattern) until you can only do a quarter turn with the length of a M5 hex key.

OP2:

Flip part around 180 degrees and center again. Make sure stock is 0.5" from back face so that the endmill does not crash into universal clamps. Feel free to check simulations on OP2 to verify location. This does the roughing and finishing of the inside of the part. Tighten the M5 bolts the same way you would with a car tire (alternating pattern) until you can only do a quarter turn with the length of a M5 hex key.

OP3:

Bolt the part to the 3DP insert. The inner sides of the insert should go onto the outer side of the universal clamp. Push the insert to the back of the universal clamp jaws. You can remove the insert in order to tighten the clamps. You will need to reset the G55 wcs for X & Y to the center of this operation since the insert will have moved the location. The operation does the roughing and finishing for the outer part. You can then do an engraving operation as you see fit.

G-CODE NOTES:

All NC Programs are ready for use and indicate setup and necessary tool. The NC Programs are also setup in the .F3Z source file if you want to make edits but I make 2 edits to any given program. The first is that from the first line in the program to WCS indicator (G55) is replaced with:

$H

G0 G90 G94 G17

G20

M3 S4000

G4 P0.5 (spinup delay)

M3 S6000

G4 P0.5 (spinup delay)

M3 S8000

G4 P0.5 (spinup delay)

G90 G94 G17

G55

which homes the machine and gives necessary spinup delay to the tool.The second edit replaces everything between the retract command (G28) and the end of the program with an absolute movement command and a homing operation.

G00 G90 G53 Z-0.02

M30

$H

LISCENCE:

CR-1:Exhaust Protector Is Available Under The CC0 1.0 License (Creative Commons Zero).

https://creativecommons.org/publicdomain/zero/1.0/

Material

Tooling

Workholding

Model Origin

The author marked this model as their own original creation.

License ©

This work is licensed under a

Sharing Without Attribution

Remix Culture Allowed

Commercial Use

Free Cultural Works

Meets Open Definition