LIGHTER ENGRAVING

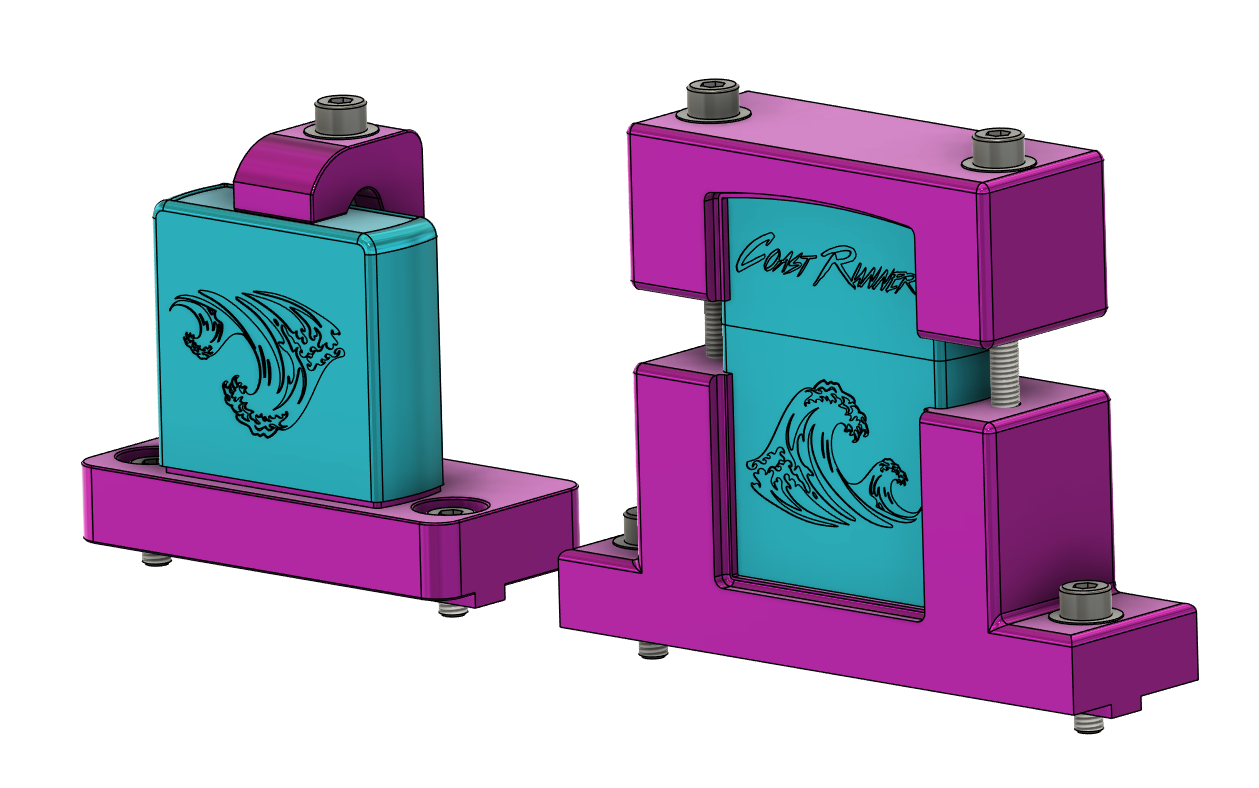

2 separate jig options and CAM for engraving a legally distinct lighter.

download3

9

1208

updated 5 hours ago

Description

TITLE:

Lighter Engraving

CR-1 Engraving Project

CREATOR:

Hearts and Minds

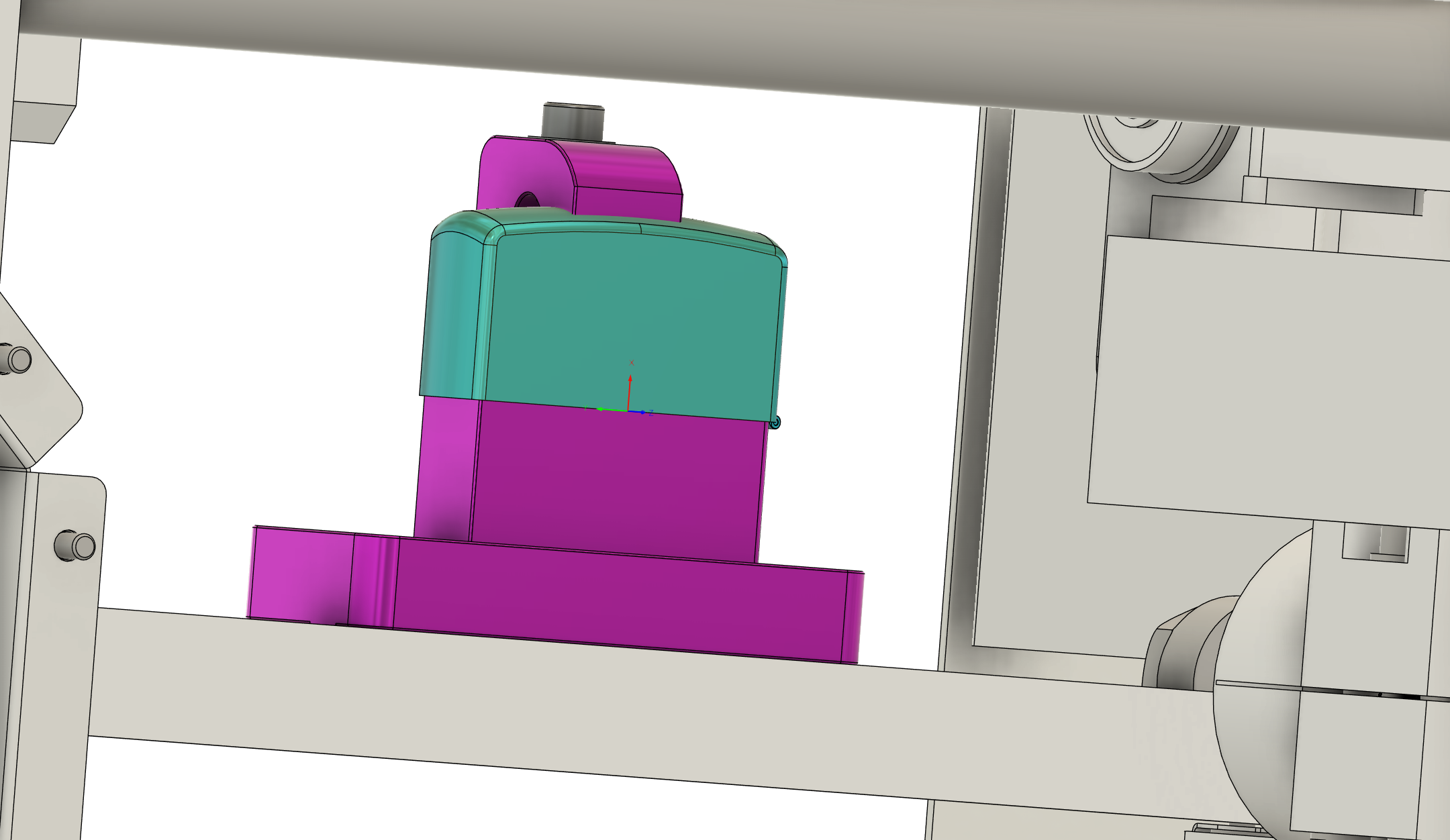

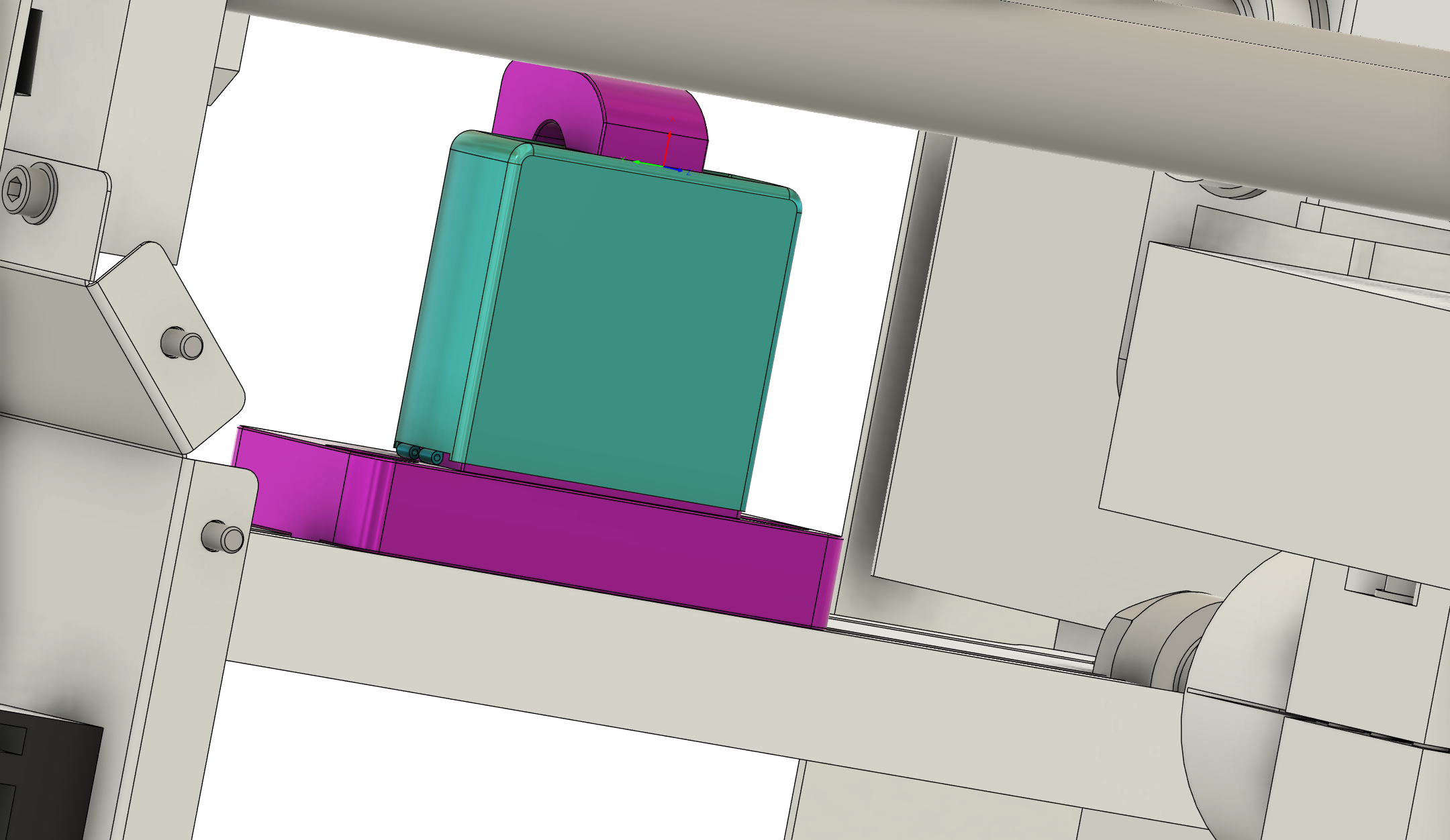

This is not a machinable from billet lighter but rather a program for engraving a lighter and 2 separate options for workholding. The CR-1 has a done of capacity but the most likely way people will open that up is through 3D printing custom workholding tailored to their part needs. In this instance a lighter model was drafted and rough exterior and interior workholding options were made using the "Combine:CUT" tool in Fusion360. There are many different ways to hold things in a stable fashion that remain square to the spindle and being able to see the pros & cons of those approaches will be essential in getting the best performance from the CR-1.

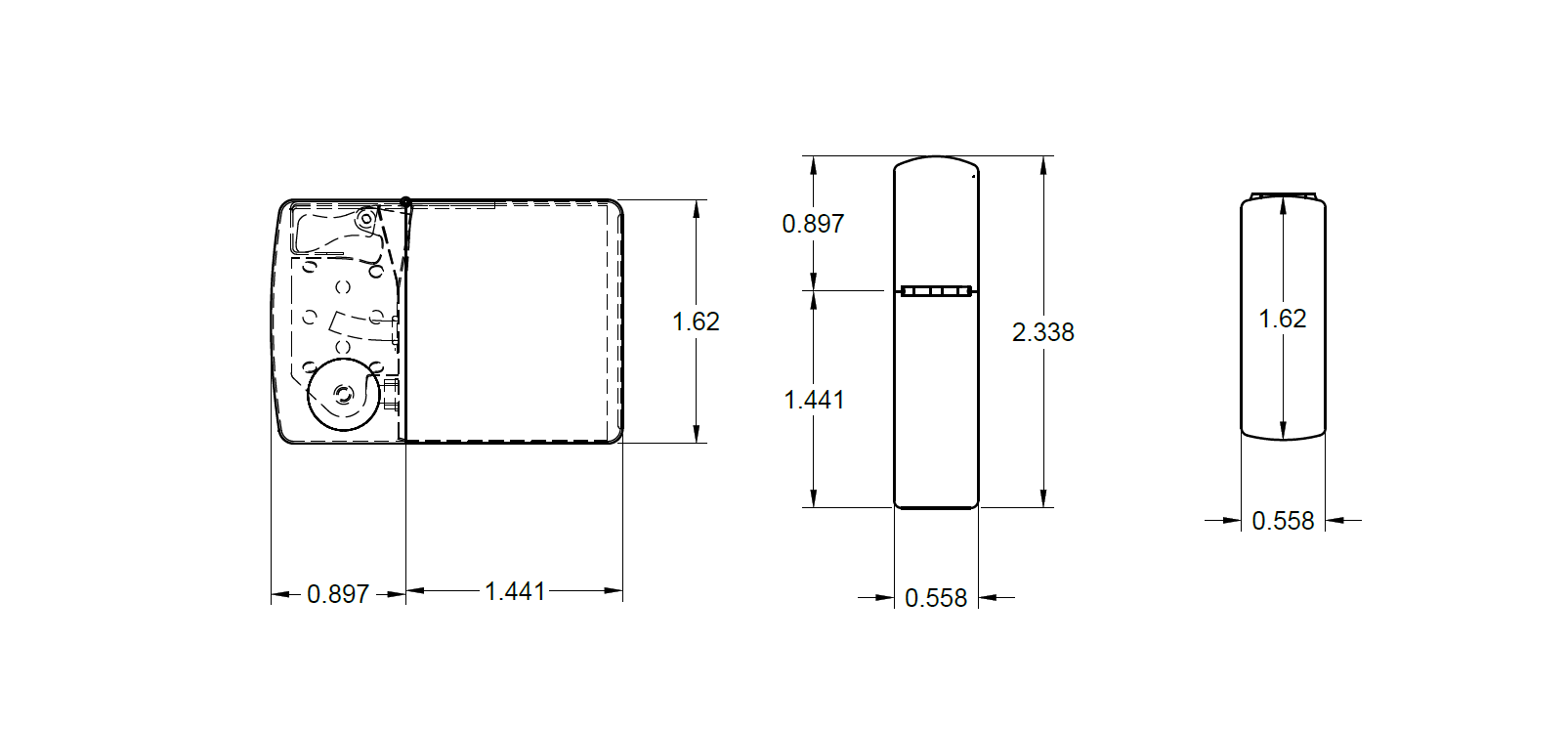

The lighter in question is a classic and well-known design. The threading for clamping force is modelled into the plastic geometry for workholding because the part will require very little force applied to be stable, the actual clamping is just to reduce vibration and ensure the part does not shift at all. For your own designs be sure to import SVGs as sketches on the face you want to mill and transfer the toolpath in the Manufacturing tab.

STOCK:

1x Legally Distinct Lighter

TOOLS:

JIG A & B have the same tool but the setting of WCS systems (either manual or conductive) are setup specific. See the WORKHOLDING section for details.

T1 (engraving only)

DIA:5/32"(.03125") OAL: 1.50"

4 Flute Ball Nose End Mill

Vendor: M.A. Ford

Product: 14003120

WORKHOLDING:

1x Lighter to be engraved.

Jigs need to be 3D Printed. 40%+ infill is fine because there is not that much force being applied to the jig itself.

The other requirements will depend on which option you go with

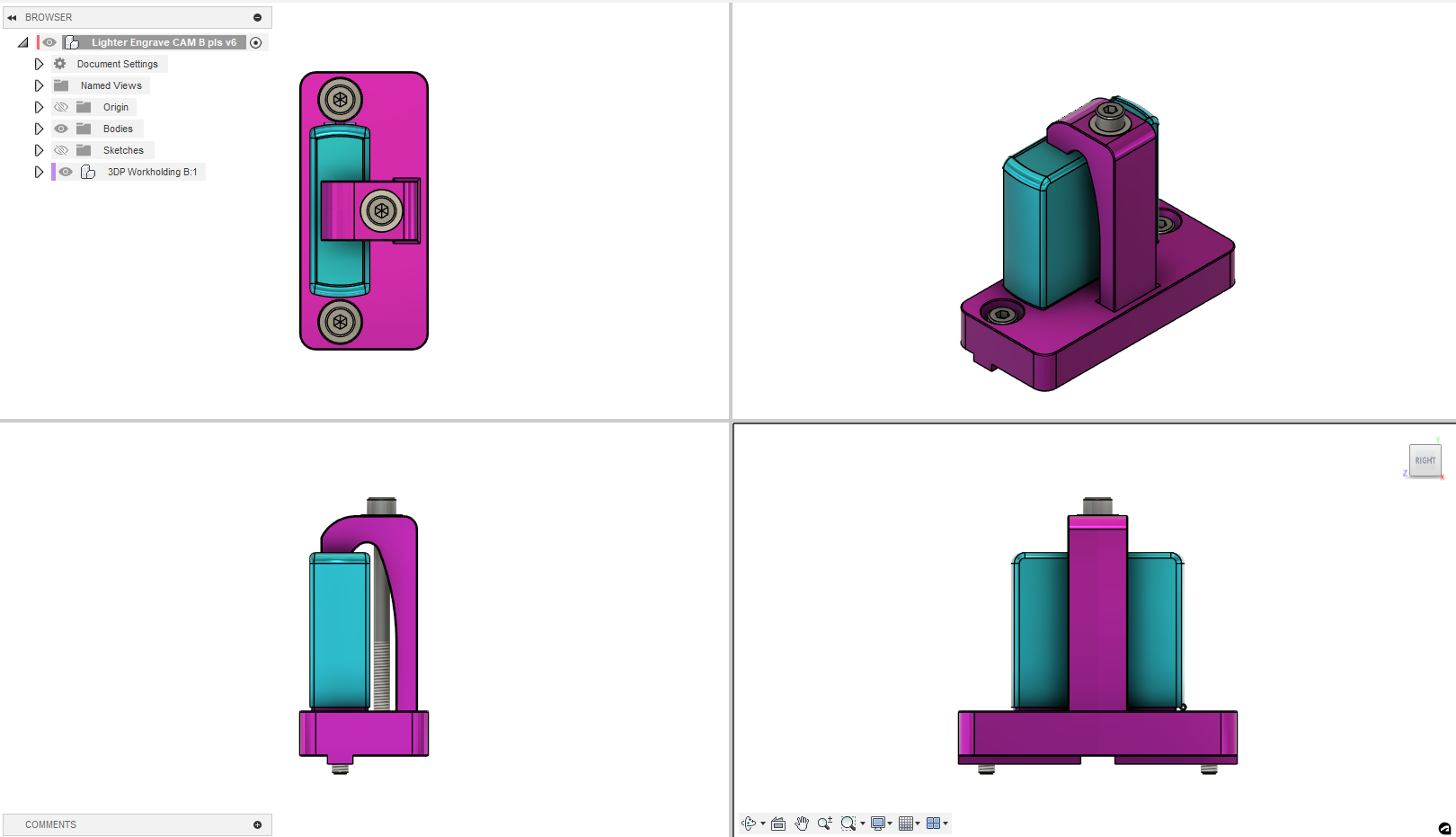

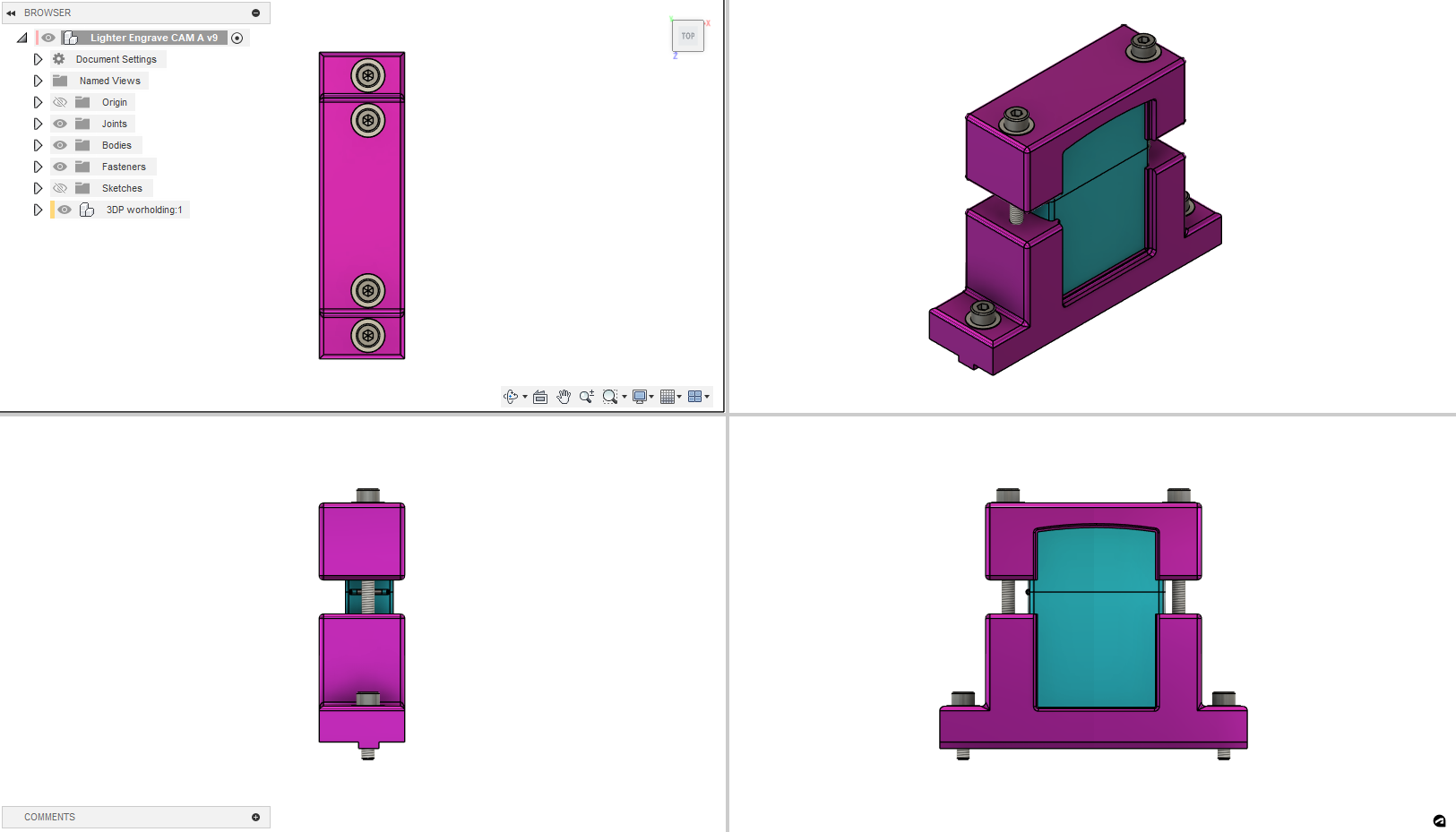

Jig A:

1x 3D printed Jig A Top

1x 3D printed Jig A Bottom

4x M4 Washers

2x T-slot nuts

2x M4x0.7 x 16mm

2x M4x0.7 x 40mm

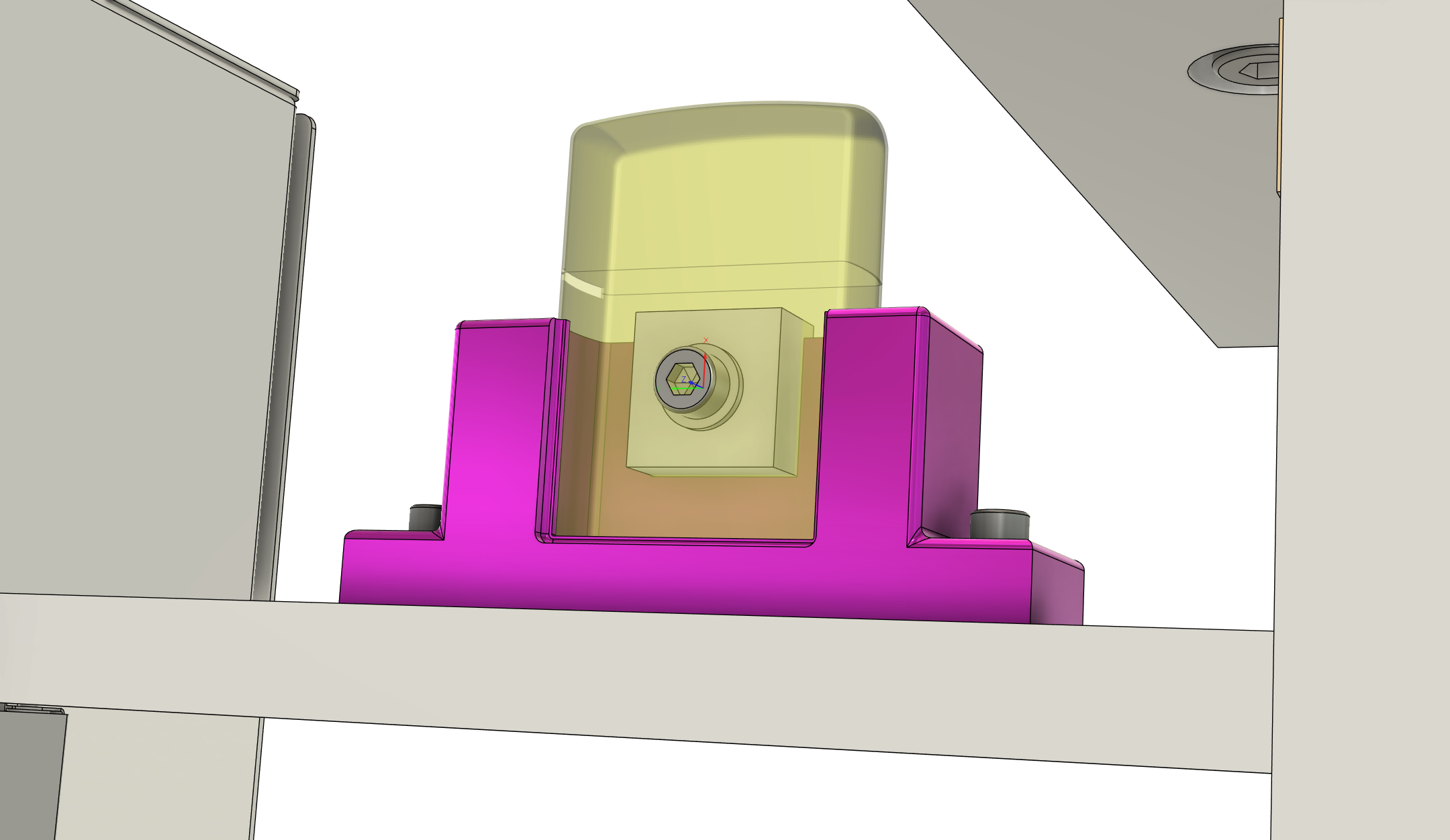

Jig A Conductive:

(everything in normal Jig A) +

1x Probe Block

2x M4 Washers

1x M4x0.7 x 25mm (minimum length, could be much longer)

1x M4 Nut

1x Probe Wire (comes standard with CR-1)

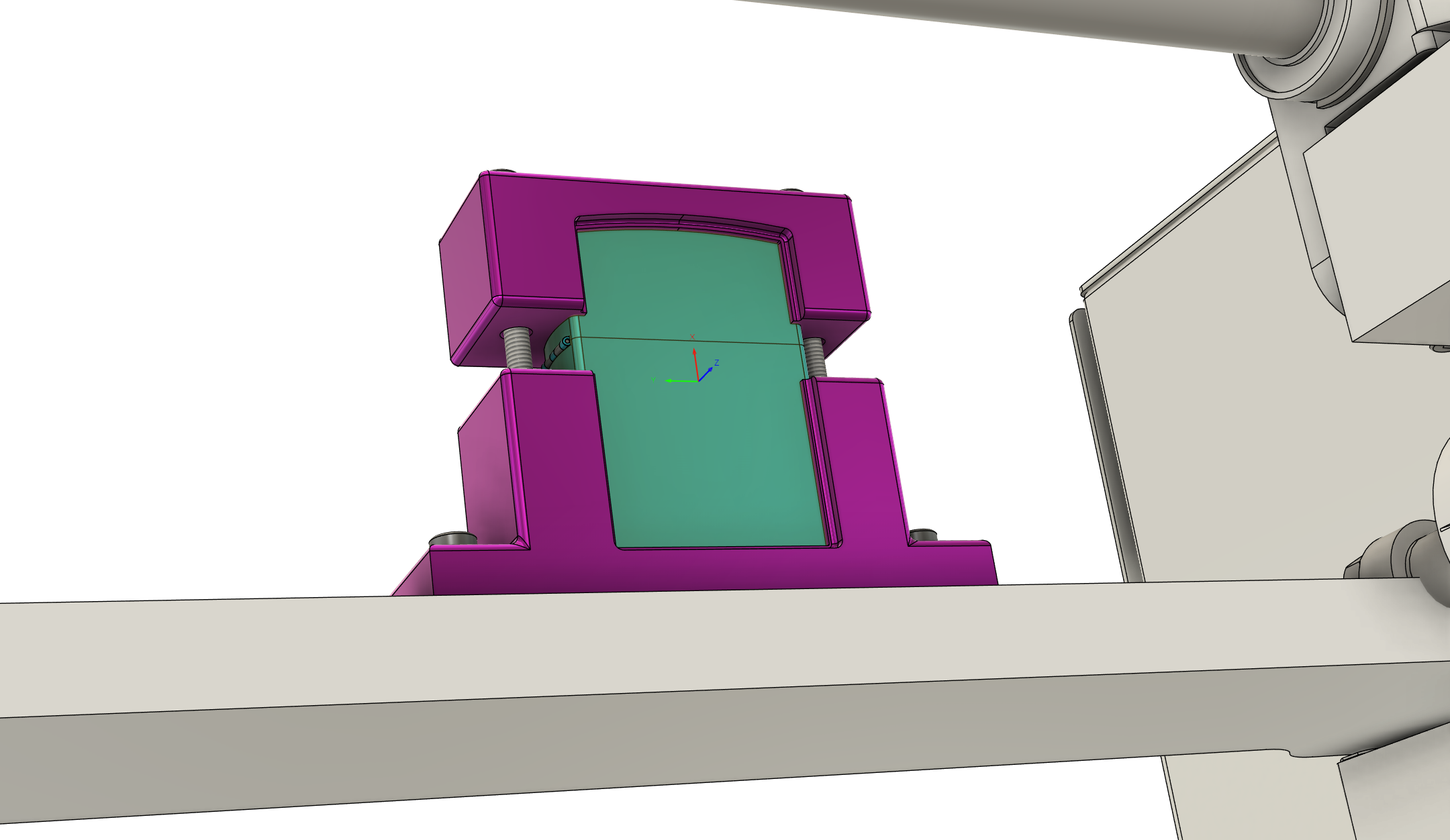

Jig B:

1x 3D printed Jig B Top

1x 3D printed Jig B Bottom

3x M4 Washers

2x M4x0.7 x 10mm

1x M4x0.7 x 50mm

WORK COORDINATE SYSTEM:

Setting the WCS is different depending on which jig and/or indicator system of choice:

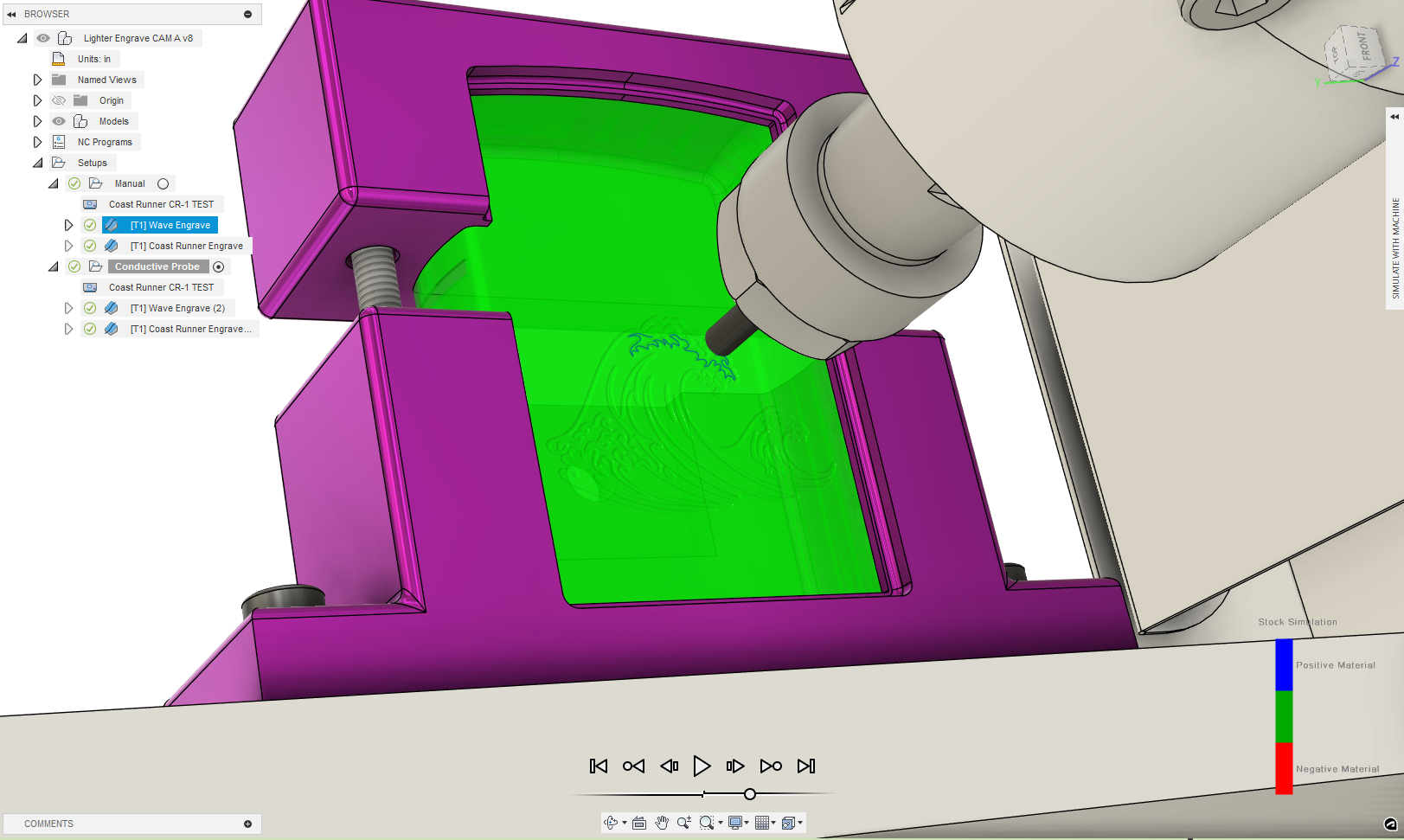

Jig A Manual WCS: G55. This is for setting yourself with an edge finder or point of a tool. This can be approximate. X/Y is center of the access window and Z is the surface of the lighter.

Jig A Conductive WCS: G54. This is for using conductivity probing. Leave the top jig off and install a probe block in the back and run a cable to the nut interface on the back of the jig. X/Y is the center of the probe block and Z is the top surface of the probe block.

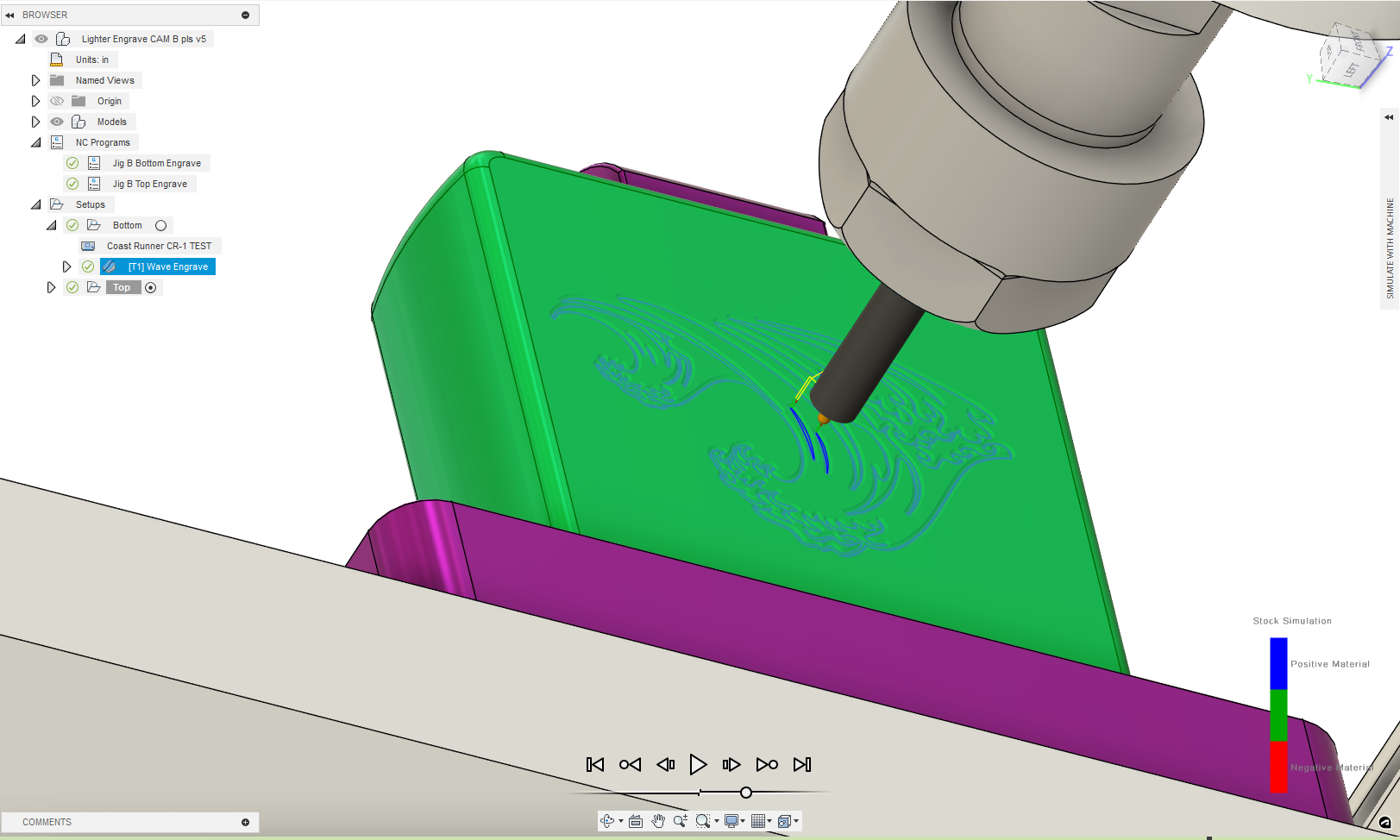

Jig B TOP WCS: G54. With the Top part of the lighter clamped on the jig, leaving the bottom hanging to the side, the Y coordinate is the center of the part, X is from the bottom edge (the bit on the part farthest down the jig), and Z is the lighter surface.

Jig B BOTTOM WCS: G55. With the Bottom part of the lighter clamped on the jig, leaving the top hanging to the side, the Y coordinate is the center of the part, X is the highest point on the part (near the clamp), and Z is the lighter surface.

OPERATIONS:

All operations are essentially an engraving operation. Major thing is to make sure that your jig and WCS setting line-up with the code you use.

G-CODE NOTES:

All NC Programs are ready for use and indicate setup and necessary tool. The NC Programs are also setup in the .F3Z source file if you want to make edits but I make 2 edits to any given program. The first is that from the first line in the program to WCS indicator (G54 or G55) is replaced with:

$H

G0 G90 G94 G17

G20

M3 S4000

G4 P0.5 (spinup delay)

M3 S6000

G4 P0.5 (spinup delay)

M3 S8000

G4 P0.5 (spinup delay)

G90 G94 G17

G55

which homes the machine and gives necessary spinup delay to the tool.The second edit replaces everything between the retract command (G28) and the end of the program with an absolute movement command and a homing operation.

G00 G90 G53 Z-0.02

M30

$H

LISCENCE:

CR-1:Lighter Engraving Is Available Under The 0BSD License (Zero-Clause BSD).

https://opensource.org/license/0bsd

Material

Tooling

Workholding

Model Origin

The author marked this model as their own original creation.

License ©

This work is licensed under a

Sharing Without Attribution

Remix Culture Allowed

Commercial Use

Free Cultural Works

Meets Open Definition